A Brief History of Sensitech: Cold Chain Monitoring

From Strip Chart Recorders to Real-Time IoT Dataloggers

On June 22, 2020, Sensitech® celebrated its 30-year anniversary as a leading provider of supply chain visibility solutions. Sensitech has relied on the talent of many individuals to reach this milestone — experts in cold chain, supply chain logistics, software, hardware and industrial engineers, alongside people with experience and creativity to deliver real value to our customers. It’s thanks to these hard-working and dedicated folks that have gotten us here today from the very beginning of the cold chain.

We are pleased to kick off our celebration with a three-part series on the history of cold chain monitoring through the eyes of our guest author and Sensitech former CEO, Eric Schultz. This series will chronicle the history of cold chain and Sensitech’s vital role as a growing, innovative industry leader.

In 1990, New England entrepreneur Sandy Santin founded a venture-backed startup, a combination of sensors and technology that he called Sensitech.

Santin believed that cold chain monitoring—tracking the temperature of food and pharmaceutical shipments as they move around the world—was an industry ripe for disruption. The cost of memory, batteries, and electronic assembly had fallen to the point where a reusable electronic monitor just might prove competitive against the industry’s dominant mechanical strip chart recorders.

The king of the cold chain monitoring industry in 1990 was Ryan Instruments. Its founder, Thomas Frank “TF” Ryan, had introduced strip charts and invented the concept of cold chain monitoring in the 1920s.

After a decade of competition in which the cold chain monitoring industry added new players and size, Sensitech and Ryan joined forces. In 2006, Sensitech was acquired by Carrier Corporation, enhancing its technological capabilities and global presence.

Today, Sensitech offers supply chain visibility services in every major market in the world. But the roots of these sophisticated, global services date back more than a century to a time when eating fresh fruit and vegetables year-round was, for most residents of the U.S., just a dream.

More Than One Orange

Until the Civil War, Americans dined primarily on wheat and beef in the North, corn and pork in the South. Fresh produce was limited by geography and season. “A child who had eaten more than one orange in a whole year,” journalist Mark Sullivan added, “was likely to be above the average in economic status and in good luck.” 1

In the 1890s, the first attempts were made to ship fresh produce in ice-packed railcars. By World War I, America had 135,000 refrigerated railcars rapidly helping to diversify the national diet.2

One of the Americans responsible for this progress was TF Ryan, who founded a wholesale fruit distributorship in Spokane in 1889. By World War I, Ryan’s organization included offices all over the western U.S., an enormous banana plantation in Mexico, and a thriving produce hub in Los Angeles. In 1917, TF Ryan was the most widely known fruit and produce jobber in America.

Ryan Fruit Company Warehouse; Source: ©1927 Charles Libby Collection, Northwest Museum of Arts & Culture, Spokane Washington

In a Class by Itself

Railcars with mechanical refrigeration would not be commercialized until the 1950s. Before that time, the secret to the successful shipment of TF Ryan’s produce was ice. Some produce shipments from California to the East Coast required rail workers to re-ice each car as many as nine times from grower to distributor.

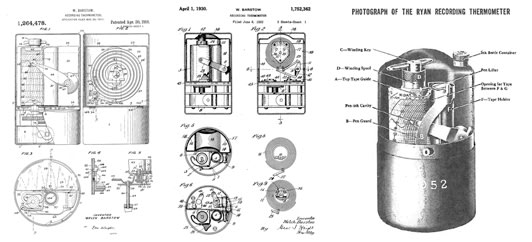

Not all railroad employees could be trusted to re-ice Ryan’s refrigerated cars, sometimes subjecting the company’s perishable cargo to excessive heat for long stretches of its journey.3 In response, in 1919 TF acquired a “thermostat” from inventor Welch Barstow which included a bimetallic coil that would expand and contract with changes in temperature.4 This coil became the “secret sauce” in Ryan and Barstow’s strip chart recorder.

The first 970 spring-wound, metal recorders were manufactured in 1923 and began riding in refrigerated cars—likely full of bananas making their way from Mexico to Seattle—to provide accountability for the producer, receiver and railroad.

Source: patents.google.com

TF Ryan died in 1942. Five years later, his widow commissioned a study of the recording industry from Booz Allen & Hamilton to determine the prospects of her strip chart company. By then, the Ryan Recording Thermometer Company had two employees, three competitors, 1,470 strip chart recorders, and served customers in frozen foods, perishable fresh foods, flour, cosmetics and film.

Ryan’s small, sturdy, reliable product was, Booz Allen wrote, in a class by itself. The consultants also noted that demand for monitoring was expected to increase because, customers told them, “the conditions that brought about the need for recording thermometers in the past will continue to exist, on a more urgent basis, in the future.” 5

Little did they know.

Cold Chain Monitoring 2.0

In 1992, two years after its founding, Sensitech launched its first electronic temperature monitor, the TempTale®1 (TT1). Designed to improve upon mechanical strip chart recorders, TT1 was the first in an increasingly powerful line of in-transit, sensor-based monitors that would soon find their way to every corner of the globe.

Sensitech, 1995.

TempTale monitors delivered accuracy, reliability and ease of use. As customers adopted this new electronic product line, focus shifted from hardware to software and analytics. Unlike the paper graphs generated by strip chart recorders, the digital data collected by a TempTale could be accumulated, sorted, and analyzed for trends. By the mid-1990s, customers were asking about new possibilities such as “predictive analytics.” Other customers wondered about the possibility of “real-time” monitoring.

A Perpetual Winter

Sensitech’s first customers included some of the world’s largest food and pharmaceutical companies. Food customers envisioned expansion, greater reliance on third-party distributors and the desire to ship more perishable, value-added food products, such as cut fruit and bagged salads.

Pharmaceutical customers coined the term “cold chain” to describe the seamless and interconnected network of refrigerated trucks, trailers, aircraft and marine containers, warehouse and retail refrigeration, and home refrigeration that relied on information systems, trained experts and superb cooperation and communications. The cold chain was a worldwide “perpetual winter,” largely unnoticed by the public, which nevertheless helped to assure the efficacy of medicines and extend the shelf life of food.

Both food and pharmaceutical customers envisioned cold chains that would become longer, more complex, more expensive, more regulated--and riskier as their businesses grew.

Innovation Continues

Sensitech responded to these needs with the creation of a Professional Services group that could help companies utilize information about their cold chain to drive process improvement and reduce costs. Through a combination of direct sales and global distributors, the company grew capable of providing virtually any cold chain in the world with an end-to-end visibility solution.

As the Internet grew, Sensitech shifted its information offerings away from desktop applications. The company’s solutions allowed customers to combine logistics information with time and temperature data in a secure, data management system.

Annual TempTale shipments grew from thousands to millions, supplemented by new monitor options such as the TagAlert® electronic indicator and increasingly sophisticated analytics.

“Our core competencies are in food distribution and food retail,” one customer said. “Sensitech’s core competencies are in cold chain management and temperature monitoring. You put the two of them together, and you have captured the best of both resources and, by doing that, you’re going to get a good solid solution to problems.”

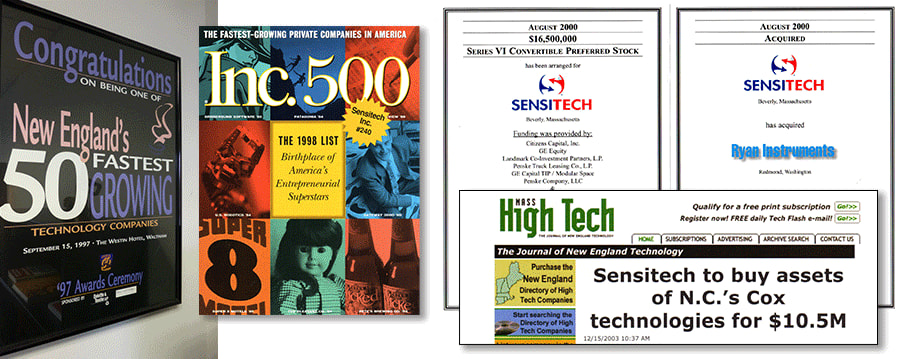

In 1997 and again in 1998, Inc. named Sensitech one of the 500 fastest-growing private companies in America. The acquisition of Ryan Instruments in 2000 and Cox Technologies in 2004 expanded the company’s global footprint and customer offerings. By 2005, new services such as Cold Chain Audit and Thermal Mapping Studies along with early efforts in track and trace technologies resulted in Sensitech rebranding its offerings from perishables temperature monitoring to cold chain visibility. 6

Need for Cold Chain Grows

While Sensitech grew, the need for the global cold chain grew even faster. New biologicals, delivery protocols, and international manufacturing were scrambling global pharmaceutical distribution. Meanwhile, the United Nations was assembling information on the global food model indicating that humankind wasted one-third of everything it produced, with perishable fruit and vegetables accounting for 40 percent of that loss. One estimate for India suggested that the country, lacking a robust cold chain, was losing up to half its produce harvest each year. 7

By 2006, Sensitech had momentum in the marketplace and was an attractive fit for a corporate partner that could help it address the increasing global opportunities in the emerging cold chain landscape.

Cold Chain Monitoring 3.0: Global Expansion Creates New Opportunities and Challenges

In the summer of 2006, Carrier acquired Sensitech. With 45,000 employees, a network of distributors and dealers spanning 172 countries, manufacturing facilities around the world, and deep roots in the commercial and transport refrigeration sector, Carrier provided Sensitech the reach that would allow its monitoring solutions to meet the growing needs of the worldwide cold chain.8

By 2012, Sensitech served 7,500 global food suppliers, 150 of the world’s largest food service companies and supermarkets, and the largest pharmaceutical and biotech companies in the world. In the summer of that year, Sensitech acquired FreightWatch International, a logistics security provider with leading-edge tracking technology and some 200 customers in electronics, life sciences, tobacco and alcohol, and luxury goods. 9

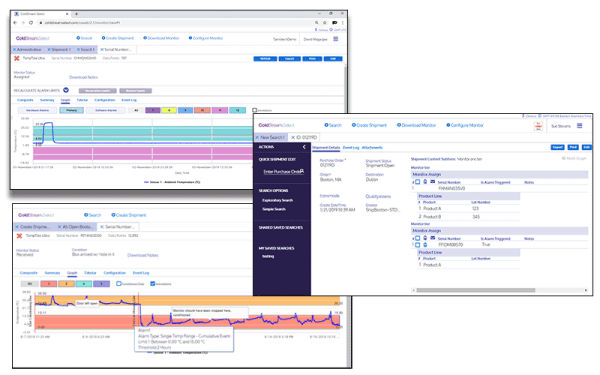

ColdStream® Select end-to-end global risk management cloud solution

“Between Carrier, FreightWatch, and a series of acquisitions, we were able to establish a true global footprint,” said Steve DiRubio, former chief operating officer, Sensitech. “We went direct in China and India, and our activities in Europe grew in size and scope to rival our traditional business lines in the Americas,” he added.

To address the increasing complexity of the cold chain, Sensitech and its customers focused around three strategic responses: visibility beyond temperature, migration to real-time, and the expansion of analytics. No longer did customers define cold chain management as a simple accept-reject decision around a single record and trip.

“We’re now talking about good cold chain management, quality risk management, security, transparency, and authenticated chain of custody,” said Henry Ames, general manager – life sciences, Sensitech. “The temperature map of each load is still critical, but we’ve taken a much more holistic view of supply chain integrity.”

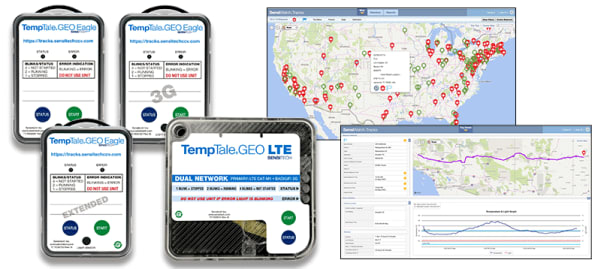

TempTale®GEO LTE and Eagle Family with SensiWatch® Tracks software

In life sciences, new predictive analytics are helping to optimize packaging and route selection. In the food segment, Sensitech customers can visualize cold chain data critical to supporting continuous improvement. For example, one large produce supplier created cold chain performance metrics that incentivized its transport companies—in some cases leading these vendors to invest in new refrigerated equipment.

“The current COVID-19 crisis has meant an acceleration of trends that already existed,” said Marc Beasley, vice president, strategic marketing and business development – food, Sensitech. “I have never seen as much discussion about cold chain visibility from managers in merchandising and logistics,” he added. “There is also a surge in home delivery, which requires focus on good cold chain management in the ‘last mile.’”

In life sciences, the COVID crisis has meant some disruption of clinical trials along with more direct-to-patient deliveries.

“We also see an industry rapidly shifting from ground and sea transport to air shipments,” Ames said. “And, we are all preparing to deliver billions of vaccine doses around the world in 2021.”

TempTale® Ultra monitor line and sample of Risk Lane Assessment

As Sensitech enters its fourth decade, its original concept of monitoring the temperature of an in-transit bulk product from its source to a distribution center has expanded dramatically.

“Our mission with both food and life science customers is to ‘de-risk’ their cold chain in ways that focus on their unique challenges,” said Mike Hurton, former president, Sensitech. “It all begins with the accurate measurement of in-transit temperature, just as it did at our founding in 1990. But, thanks to our superb global team and our relentless emphasis on innovation, we are using new tools—from real-time sensors, the Internet of Things, global information-sharing and rich analytics--to create true cold chain visibility.”

Eric B. Schultz is the former CEO of Sensitech Inc. His most recent book is "Innovation on Tap: Stories of Entrepreneurship from the Cotton Gin to Broadway’s Hamilton".

- Mark Sullivan, "Our Times: The United States 1900-1925, II, America Finding Herself," New York: Charles Scribner’s Sons, 1927, 488-489.

- Jonathan Rees, "Refrigeration Nation," Baltimore: Johns Hopkins, 2013, ebook locations 1878-1973.

- Author, personal communication.

- See source 1 and source 2.

- “Market Survey for the Ryan Recording Thermometer Company,” Booz Allen & Hamilton, November 10, 1947.

- Customer quote and rebranding information from “Sensitech: Confidential Descriptive Memorandum,” CIBC World Markets, November 2005.

- Mandyck and Schultz, 60 (1/3 estimate) and 40 (India estimate).

- Carrier Corp datasheet, April 2005, Sensitech files.

- Lori Hawkins, "Austin-based FreightWatch Sold to Massachusetts Company," Austin American-Statesman, Gannett Co. Inc, Sept. 21, 2012.